Hydraulic

bath bomb press

Looking to enhance your Bath Bomb Production with reliable and efficient machinery? Our Automatic Hydraulic Bath Bomb Press Machines are specifically designed for the Bath Bomb Industry to ensure consistent, high-quality results.

With over 20 years of experience in hydraulic press manufacturing and more than a decade of expertise in Bath Bomb Machine, we are able to offer top-tier solutions that streamline your production process.

Our machines not only optimize efficiency but also offer easy mold customization, allowing you quickly start your next project by simply changing molds.

working principle

Schematic of pressing process

In this dynamic demonstration, you will see the synergy of the parts collaborating to shape bath bombs, and learn the basic workings principle of our Automatic Bath Bomb Machine from the individual die components.

While this demo provides an visual insight, the actual workings of the machine is much more complex, and we will explore every detail of the machine in the subsequent presentation.

Table Of Contents For This Page

We have prepared detailed information on this page for you to learn more about our Hydraulic Bath Bomb Press. To ensure that you can quickly find the information you need, we have prepared this content catalog, which, when click on, will take you to the appropriate loacation.

Best selling bath bomb press

Compared with similar companies in Europe and America, our Hydraulic Bath Bomb Press have advanced automation technology, which greatly reduces labor requirements. Furthermore, as shown in the picture below, the first type of machine not only high efficiency, but also can produce both wet and dry powder.

LBP-50

- Automatic

- Molds: Customizable

- Raw material: Ideal for wet and dry powders

- Production capacity (45mm): 1,920-6,000 pcs/hr

The production capacity of a machine is directly proportional to the pressure, this is a 50-ton Automatic Bath Bomb Machine that meets the needs of most medium-sized Bath Bomb Manufacturers. The machine can produce not only wet powder bath bombs but also dry powder.

LBP-10

- Automatic

- Molds: Customizable

- Raw material: Wet powder only

- Production capacity (45mm): 1,500-4,300 pcs/hr

With a Fully Automated Bath Bath Machine, the production process requires little to no human involvement, It greatly increases productivity and producing approximately twice as much as a Semi-automatic Bath Bomb Machine below.

LBP-10S

- Semi-automatic

- Molds: Customizable

- Raw material: Wet powder only

- Production capacity (45mm): 900-2,150 pcs/hr

If your output requirements are not particularly high, you can opt for this semi-automatic model, which differs from a fully automatic press only in that the pressed bath bombs needs to be removed manually, which will be more time-consuming. However, it also lowers the investment threshold due to the reduced configuration.

| Model | Capacity (Max.) | Pressure | Power | Voltage | Machine weight |

|---|---|---|---|---|---|

| LBP-10S | 1,800 pcs / hour | 10T | 8.5Kw | 220V/380V 3-Phase, Customizable | 1,500Kg |

| LBP-10 | 4,500 pcs / hour | 10T | 8.5Kw | 220V/380V 3-Phase, Customizable | 1,800Kg |

| LBP-30 | 6,000 pcs / hour | 30T | 9.5Kw | 220V/380V 3-Phase, Customizable | 2,000kg |

| LBP-50 | 7,500 pcs / hour | 50T | 10Kw | 220V/380V 3-Phase, Customizable | 2,500kg |

| LBP-100 | 9,000 pcs / hour | 100T | 12Kw | 220V/380V 3-Phase, Customizable | 3500kg |

| LBP-200 | 9,600 pcs / hour | 200T | 15Kw | 220V/380V 3-Phase, Customizable | 4350kg |

The Max. production in the table above are estimated based on wet powder, 50mm diameter spherical molds, depending on the number of molds.

Since mold prices increases with quantity, the number of molds should be determined according to your actual production demand.

All you need to know about our

hydraulic bath bomb press

We chose the hydraulic press as the manufacturing equipment for bath bombs because the force and pressure that is applied by a hydraulic press is far superior to any other material shaping and deforming method. One of the necessities of a deforming process is that the device applying the pressure be able to maintain its strength throughout an application, and it is precisely the hydraulic press that can achieve full tonnage anywhere throughout the stroke.

We will custom build Hydraulic Bath Bomb Press based on your needs and specifications, it will equipped with hoppers, ejectors and conveyor to help you realize the fully automatic production of bath bombs.

In addition to Hydraulic Bath Bomb Press, we also have Servo-hydraulic Bath Bomb Press; It is mainly for hard-to-form materials, as well as for forming complex shapes; servo hydraulic presses with ram that can slow in, quick out at the BDC, to improve the press fastness, reduce cracking and rebound.

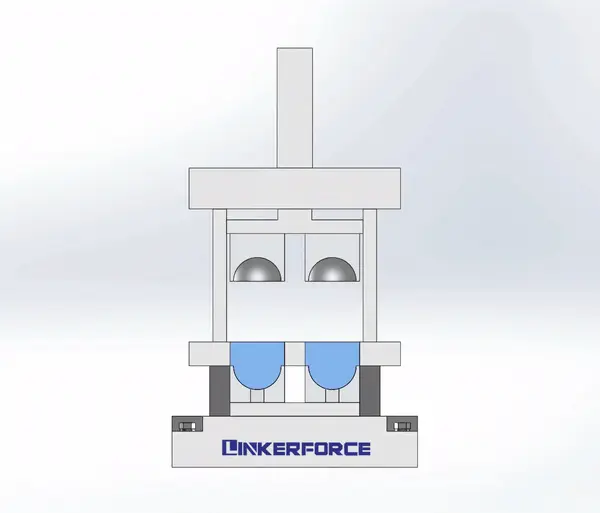

Composition of

bath bomb machine

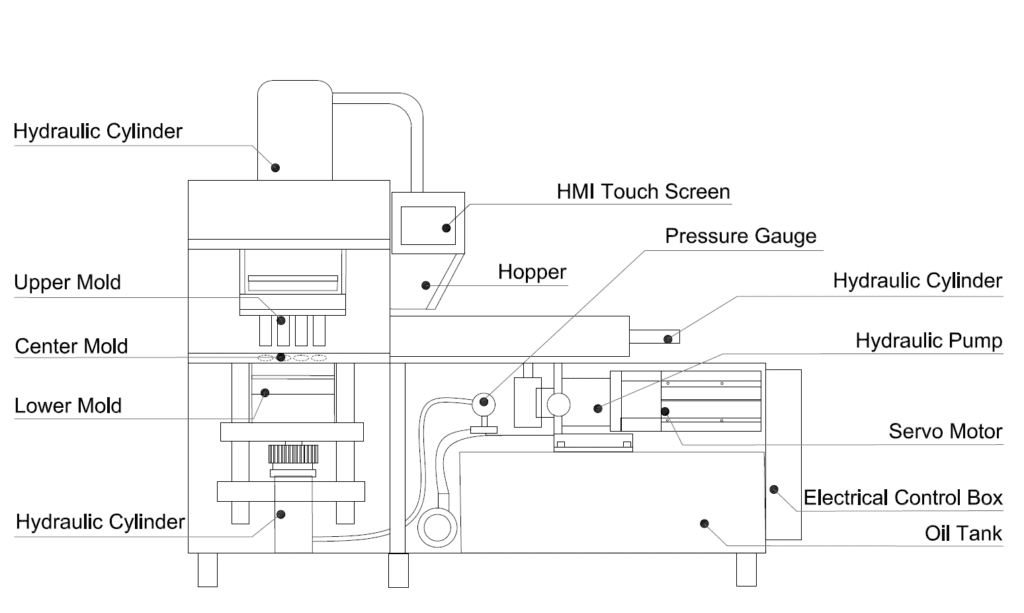

The mechanism of a Hydraulic Bath Bomb Press consists of a mainframe, power system, and control system. The upper and lower half of the mold match the shape of the bath bombs to be produced, equipped with a fixed center mold and fluidized fill system for product uniformity.

The powder mixture is automatically dropped into the lower half of the mold via the hopper and the ram lowers the upper half to compress the powder to form the desired shape of bath bomb.

The compressing process deform the particles of the mixture powder and significantly increase its density. The following are the main components of the machine.

-9.19-1024x686.jpg)

Power system

The power of the Automatic Bath Bomb Machine comes from the hydraulic system, which works on the principle that the hydraulic pump forced hydraulic fluid into a double-acting piston. The passage of the fluids between the two pistons creates pressure to drive the upper mold on a hydraulic press downward onto a mixture powder that is deformed to produce a desired bath bomb shape.

The picture on the left shows our Automatic Hydraulic Bath Bomb Press, which uses a servo motor as the main drive source. The speed and position of the mold movement is controlled by adjusting the speed and direction of the servo motor.

The hydraulic system of our machines is integrated below the machine, and the built-in design keeps your workspace clean and organized.

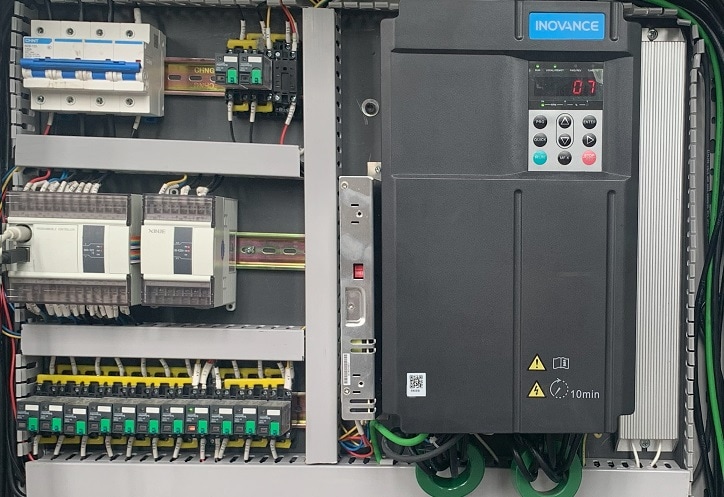

Control system

This is the brain that controls the operation of the Automatic Bath Bomb Machine and is housed in a separate cabinet, the PLC programmable control system as well as the HMI touch screen and sensors distributed in various locations, make it user-friendly and easy to operate, even for those not well-versed in machines.

It can also exchange signals with external equipment (e.g. vacuum loader, conveyor) and produces bath bombs automatically throughout the process; and, in addition to the light curtain protection, we have equipped an extra emergency stop to provide a double guarantee for the safety of workers.

Our Automatic Bath Bomb Machine can also store multiple programs to match your different production needs. For example, two-color, single-color, add toys, etc.

Hopper

Our Automatic Bath Bomb Machine are equipped with hoppers, the powder mixture is automatically transported and filled into the lower mold through this hopper with the control system mentioned above.

We can also configure two hoppers on one machine for the automated production of two-color bath bombs.

Moreover, by adding a vacuum loader, you can also realize the automatic powder loading, which reduces downtime for replenishment during production, and increases production capacity more efficiently.

mold

This is complete set of molds, three-piece powder molds consists of floating cavities (upper and lower mold), a fixed cavity (middle mold) and an ejector. when pressing, the lower mold will remain fixed and the upper mold will drop down to press, which can press different powdered materials into shapes, designs, and densities.

Our molds are designed to be removable, all you need to do is change the mold, and you’re ready to tackle the next project.

feel free to contact our knowledgeable team

Whether you’re a seasoned professional or just getting started, our Hydraulic Bath Bomb Press are designed to make your work easier and more efficient.

Key Considerations for Machine Purchase

In the purchase of Bath Bomb Production Equipment, you need to pay attention to the following points, which will be more helpful for your equipment selection and supporting equipment selection.

1.production capacity

For the same model of Bath Bomb Machine, the number of bath bombs that can be made at a time depends on the size of the mold and the density of the powder, Since the maximum pressure of the Bath Bomb Machine is fixed, the larger the product size, the lower the output per press and vice versa;

In addition, the pressing frequency of the Bath Bomb Machine is basically fixed. For single-color bath bomb balls, it is usually 5 presses/minute, and for two-color, or those that require built-in toys, it is 3 presses/minute;

2. Machine selection depends on powder Ingredients

The powder for bath bombs are divided into two categories: dry and wet. For wet powder, you should be able to squeeze it into a lump (like wet sand) and then break it up again easily. For dry powder, it is very difficult to squeeze it into a lump by hand, because its much denser than wet one.

Wet powder can be pressed by 10 tons machine or even by hand, while dry powders require a 30-ton or larger machine to produce. In addition, for a 30-ton machine, more bath bombs can be produced per press for wet powder ingredients than for dry one.

Therefore, we can not simply judge the value of the Hydraulic Bath Bomb Press from the capacity, but to combine the characteristics of the powder and capacity, and then rationally choose the right equipment for ourselves.

3. Materials used

When purchasing a Bath Bomb Machine, you need to understand that the production of bath bombs is only the basic function of the machine, as the equipment that will be with you for years or even decades, its quality is the top priority.

For example, the strength of the load-bearing steel plate is very important, otherwise after thousands of high-intensity pressing, the plate is likely to be deformed, which will lead to mold misalignment and damage to the mold. And for molds that come into direct contact with powder, corrosion resistance, abrasion resistance and hardness must be considered.

4. Value of machines

When buying a Bath Bomb Machine, it is important to consider its expandability.

For example, if you want to produce a product of a different shape or size, will the machine you purchased still be able to do the job, or will you have to order another Bath Bomb Machine at the same price? If you receive an order from the children’s market for a toy to be added to an existing shape, will your machine be able to effectively meet this new demand?

These are potential costs you need to consider when purchasing a Bath Bomb Machine to maximize the value of your purchase, This is exactly what we took into consideration when designing the machine.

5. The entire production line system

It depends on how you balance equipment input cost and labor cost.

At the beginning of your project, you may consider purchasing just one Bath Bomb Machine with a few workers to complete the entire production process from powder mixing, powder filling, bath bomb production to bath bomb packaging.

When you have a steady flow of orders, then equipped with automated equipment such as mixers, vacuum loaders and packaging machines to reduce the fixed labor cost incurred every month.

Most Frequently Asked Questions and Answers

FAQs

What are the advantages of your machine?

With our independent R & D team, we can design and manufacture each project according to customers' individual needs, and then you can use our hydraulic bath bomb machine to produce your ideal bath bombs.

Automation: The whole process from filling, forming to producing are all automated, thus increasing production efficiency and reducing labor costs.

Customization: Our bath bomb machine can be adapted to different production requirements by changing molds, pressures or programs. In the case of the LBP-50 model, the ability to produce 25PCs (45 mm) at a time can be adjusted to 50PCs (38 mm) at a time by adjusting these aspects.

Noise: (In many countries, noise is used as a testing criterion) A major concern for monitoring agencies is the amount of noise that employees are exposed to during the workday. Excessive noise can result in serious medical and mental issues that lead to absenteeism and production stoppages. Due to the hydraulic drive, there are very few moving parts, its operation noise level is significantly reduced.

Can I visit your factory in China?

Yes. you are warmly welcome to visit our factory and experience our machine for yourself.

We are sure you will be impressed.

What information do I need for a quote?

Some of the basic information we need includes the shape and size of the bath bombs you need to produce and whether you are using dry or wet powder, additionally, we need to know the your capacity requirements.

What is the ordering process?

Custom design: Design the mold and equipment

Drawing: Making the mold drawings for your checking.

Order Confirmation: Sign contract after drawing confirmation.

Deposit: 30% deposit before production.

Production: We will arrange production.

Balance payment: Payment after inspection, balance before shipment.

Shipment: We will ship the machine to the destination port.

Confirm: bill of loading, commercial invoice, packing list, etc.

After-sales service

What are your payment terms?

We accept 30% T/T deposit before production and 70% T/T balance before shipment.

Our payment terms include EXW, FOB, CFR, and CIF.

How do I test the machine before shipping?

We rigorously test each machine for 48 hours prior to shipment to ensure performance and quality.

We also provide test videos to our clients for review and approval.

What are the details of packaging?

To ensure the integrity and safety of the equipment, we will use a steel frame to fix the whole machine and pack it with plastic film and export plywood box.

How do clients track their machines?

From assembly, debugging to delivery, we will send relevant pictures and videos so that our customers can follow the production process.

We will also update the latest information to our customers as our engineers complete the development of special requirements.

How long does it usually take to receive machine?

This depends on the difficulty of customizing the equipment and the speed of customs clearance and logistics. Machines are built on order and general lead time is 25~35 business days.

Depending on your destination, delivery time is typically 5-7 days by air and 20-35 days by sea;

How long does it take to install?

Don't worry about the assemble process, our bath bomb machine is pre-assembled and shipped in a wooden case. When you receive it, just simply connect it to the factory power supply, add hydraulic fluid to the machine and it’s ready to use; this all takes just one day.

So far, there have been no customers complaints about this.

Do you provide overseas after-sales service?

We will provide free online support and video tutorials.

However, if the customer needs on-site technical support, we can also send engineers to the customer's factory, and the customer needs to pay the corresponding service fee, including round-trip airfare, boarding & lodgings, visa fees, as well as a daily service fee of 200 U.S. dollars.

Note: For spare parts damaged due to quality issues, we will provide replacement parts free of charge during the warranty period.

Maintenance

In the heavy machinery industry, equipment maintenance is one of the planning factors of the budget.

In contrast to various mechanical processes that include crankshafts, flywheels, brakes and clutches, we have chosen hydraulics as the drive system for our bath bomb machine, and this simplified structure significantly reduces maintenance costs(including time costs).

Our operating instructions list detailed maintenance methods depending on the machine.