Pneumatic

bath bomb press

Our Pneumatic Bath Bomb Presses are designed to provide superior bath bomb production performance at an extremely cost effective machine price, since it only requires compressed air to drive the cylinder for reciprocating motion, making it an economic solution in bath bomb production.

Due to the low pressure used by the pneumatic system, it is suitable for lightweight operations and is ideal for startups, low investment, no extensive space required, you can easily mass produce bath bombs.

Take your bath bomb business to new heights with our Pneumatic Bath Bomb Presses.

working principle

Schematic of pressing process

In this dynamic demonstration, you will see the synergy of the parts collaborating to shape bath bombs, and learn the basic workings principle of our Bath Bomb Maker Machine from the individual die components.

The demo provides an visual insight and the actual operation of the machine is as easy as the demo, we will explore every detail of the machine in the subsequent presentation.

Table Of Contents For This Page

We have prepared detailed information on this page for you to learn more about our Pneumatic Bath bomb Presses. To ensure that you can quickly find the information you need, we have prepared this content catalog, which, when clicked on, will take you to the appropriate location.

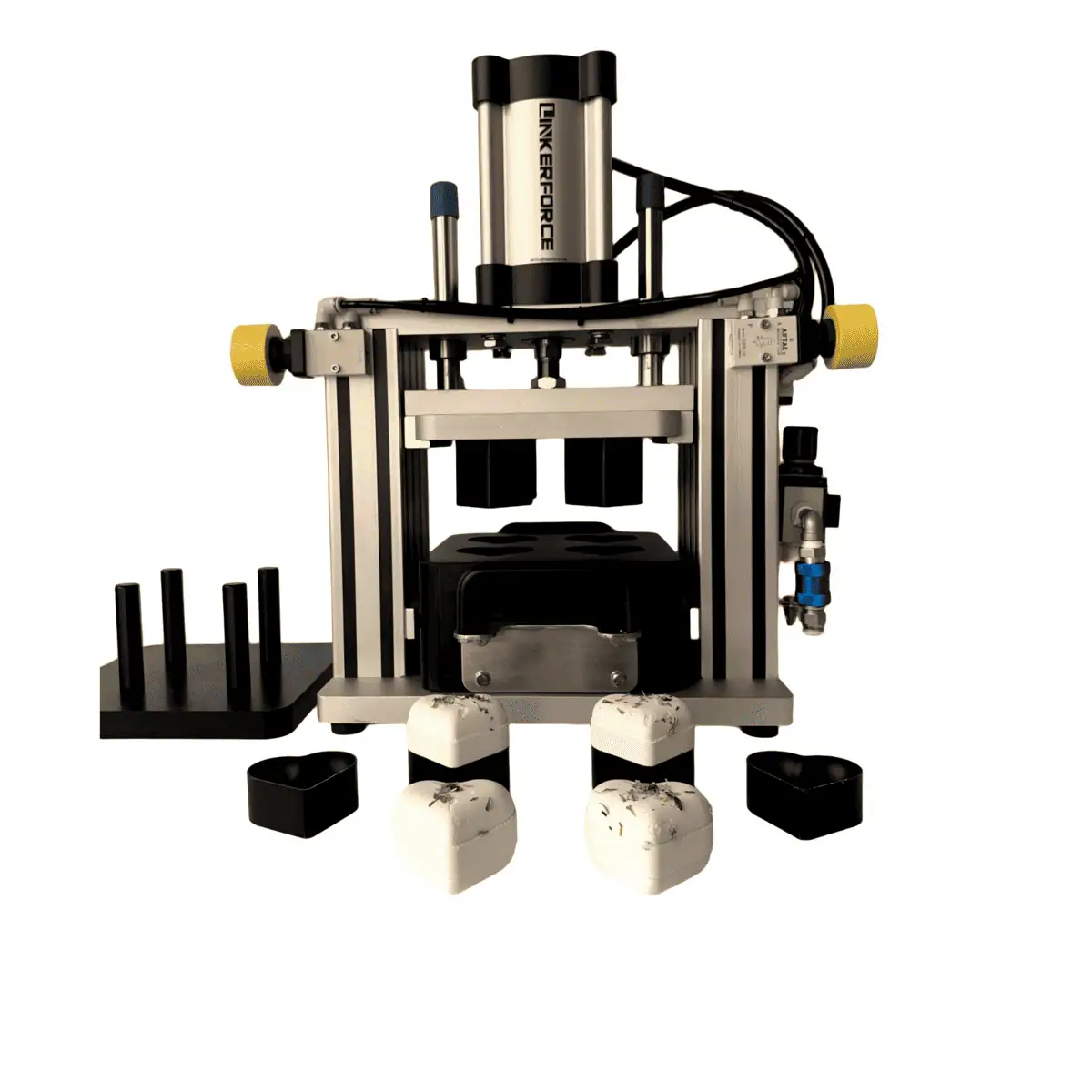

Best selling bath bomb press

Our Pneumatic Bath bomb Presses are tailored for new entrants in the production of bath bombs and are compact enough to require no dedicated space, It is ideal for home based business and provides a perfect start to your entrepreneurial career.

It is also easy to operate and produce consistent bath bombs regardless of operator, furthermore you can quickly load and unload molds in less than 15 seconds, whether you an experienced bath bomb maker or just starting out, you can easily produce bath bombs in a variety of shapes and sizes.

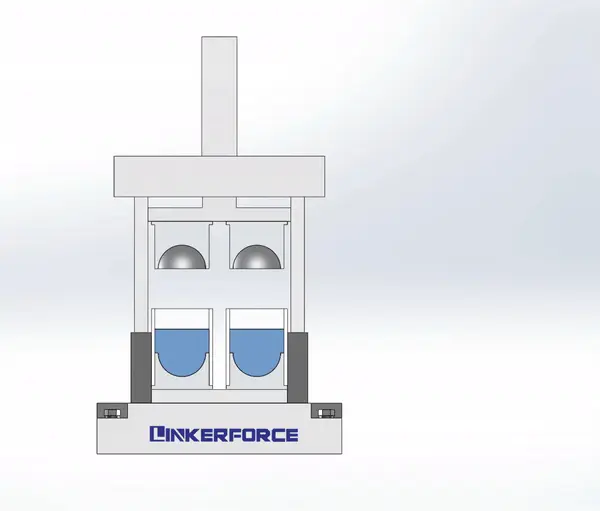

LBP-02

- Pressure: 200Kg

- Molds: Customizable

- Raw material: Wet powder only

- Production capacity: 240 pcs/hr

This Bath Bomb Maker Machine comes with two customized Aluminum Bath Bomb Molds and fully assembled, you can provide personalized solutions by customizing multiple sets of molds to meet the unique preferences of your clientele.

LBP-04P

- Pressure: 400Kg

- Molds: Customizable

- Raw material: Wet powder only

- Production capacity: 480 pcs/hr

The performance of this four cavity Bath Bomb Maker Machine is basically the same as the LBP-02, it comes with four customized Aluminum Molds and an easy-to-use ejector plate for quick removal of the completed bath bombs with at least twice the output of LBP-02.

LBP-04L

- Pressure: 400Kg

- Molds: Customizable

- Raw material: Wet powder only

- Production capacity: 480 pcs/hr

This Bath Bomb Maker Machine has the same output as the one described above, the multi-cylinder configuration optimizes production capabilities, Install 4 different sized molds at a time, allowing you to create multiple bath bombs at the same time.

Features

- Precision alignment

- Space-Saving Design

- Easy quick mold switch

- Simple and fast operation

- Customized molds of various shapes

- Weighs approximately (LBP-02): 15kg

- Weighs approximately (LBP-04P): 30kg

- Driven by an air compressor (not included)

All you need to know about our

Pneumatic bath bomb press

We chose a pneumatic solution for our entry-level Bath Bomb Maker Machine because the pneumatic systems have a simple piping structure and ease of operation. There is low learning curve for beginners.

Our equipment is made from high quality industrial components that are built to last, pneumatic cylinders, for example, are well-established components that we can easily find in any mechanical system. The frame on the other hand, is built from lightweight, high strength and non corrosive extruded aluminum.

We will take an in-depth look at how each operational component works, from the pneumatic cylinder to the manual pneumatic valve to the air compressor.

Composition of

bath bomb machines

The mechanism of a Pneumatic Bath Bomb Press consists of a mainframe, power system, and control system.

The upper and lower half of the mold match the shape of the bath bombs to be produced, the powder mixture is added into the lower half of the mold manually and the cylinder lowers the upper half to compress the powder to form the desired shape.

The compressing process deform the particles of the mixture powder and significantly increase its density.

The following are the main components of the machine.

-1024x685.jpg)

actuator segment

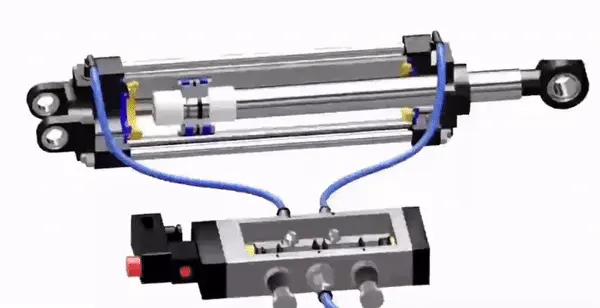

Cylinders are pneumatic system components that convert pneumatic energy into mechanical energy.

What you see here is a double-acting cylinder, which is an actuator, the cylinder rod moves in and out of the cylinder, there by moving the upper mold that is connected to it.

Double-acting cylinders have two ports for air intake at both ends of the cylinder covers, connect the air tubes all together as shown in the picture.

When pressurized air enters through the port on the rod cover side and the cylinder rod is retracted (move upward), air is let out through the head cover side, when pressurized air enters through the head cover port, and air is let out through the port on the rod cover side making it move downward.

air control segment - direction

In the control segment, the airflow direction and volume can be controlled to control the movement of the actuator, we chose the simplest manual pneumatic valve to control the direction of the air flow, by changing the direction in which the compressed air flows, the actuator can be moved upward or downward.

Here I’ll also put up a dynamic demonstration of the internal switching of the valve so you can better understand how it controls the direction of airflow, and thus the cylinder rod that drives the upper mold to press the bath bombs.

air control segment - speed

Here is the speed controller, it is a pneumatic component that is used to control the amount of air flow, and help us regulate the drive speed of the actuator.

You can see, there are two small holes, one for the pneumatic port of the cylinder, and the other to the pneumatic tube, and there are knobs on it that can controls the amount of air, so that air can be adjusted by rotating it.

Speed decreases as we tighten the knob and the speed increases as loosen the knob.

mold

Three-piece powder molds consists of upper mold, lower mold and middle mold.

When pressing, the lower mold will remain fixed and the upper mold will drop down to press, which can press powder into different shapes and designs.

Our molds are designed to be removable, You can replace it in just 15 seconds, and you’re ready to tackle the next project.

air compression segment

An air compressor is required to run our Desktop Pneumatic Bath Bomb Press.

The air compressor intakes the air in the surroundings and compresses it, the compressed air is then stored in the air tank below.

When force is needed for movement, the compressed air is conveyed toward the actuator segment via a pipe.

The force of this pressure can then be utilized to drive the Bath Bomb Press.

feel free to contact our knowledgeable team

Whether you’re a seasoned professional or just getting started, our Pneumatic Bath Bomb Presses are designed to make your work easier and more efficient.

Key Considerations for Machine Purchase

In the purchase of Bath Bomb Equipment, you need to pay attention to the following points, which will be more helpful for your equipment selection and supporting equipment selection.

1.production capacity

The production capacities 240/hr or 480/hr listed above are estimated based on our actual operations with one person and one set of molds, this takes into account the time you will need to manually add powder to the mold and the time it takes to manually remove the bath bombs after pressing (These factors that need to be done manually are what you need to take into account when doing side-by-side comparisons).

Productivity can be increased by ordering 2-3 sets of the same mold size, many of our clients are currently implementing this approach with great success.

If you have one or two people working with you, one mixing, one operating the Bath Bomb Machine and one unloading the bath bombs from the molds, you can easily double your production capacity, this is an excellent choice for a home based business.

2. Machine selection depends on powder Ingredients

The powder for bath bombs are divided into two categories: dry and wet. For wet powder, you should be able to squeeze it into a lump (like wet sand) and then break it up again easily. For dry powder, it is very difficult to squeeze it into a lump by hand, because its much denser than wet one.

For our Pneumatic Bath Bomb Press, due to the low pressure, it can only press wet powder, for dry powder, consider at least 30 tons of Hydraulic Bath Bomb Press for efficient production.

3. Materials used

Even though the cost is low, the quality of the equipment should be prioritized when investing in a Desktop Pneumatic Bath Bomb Press.

First of all, the quality of the equipment affects its lifetime, for example, you need to consider whether the strength of the frame is enough, or if the selected mold is corrosion-resistant, will it be broken down or degraded by citric acid, essential oils, vegetable oils, etc. causing the mold to slowly deform and become unusable.

Secondly, If the mold material is not selected properly (e.g. plastic), it will breaking down, and becoming part of your bath bombs during the manufacturing process due to corrosion, then your customers will be exposed to the potential toxicity inherent in decomposing plastics.

4. Operated by an air compressor

As mentioned earlier, the up and down reciprocating motion of the cylinder is driven by compressed air supplied by an air compressor, however, air compressors are not included in our sales packages, as they are a well-established and easy-to-find product, can be bought at your local hardware stores or online.

Power required:

LBP-02: Min. 90 PSI pressure, 3 gallon air tank size.

LBP-04P: Min. 110 PSI pressure, 8 gallon air tank size.

Most Frequently Asked Questions and Answers

FAQs

potential market

Congratulations on choosing bath bomb, a fantastic product to kickstart your business, it can be sold through multiple channels, from online platforms like Amazon to offline markets.

It has attractive returns, with retail prices typically ranging from $3-5 per bath bomb and costs under $0.5 per unit (this is based on the cost of the basic Ingredient for 300 bath bombs, buying in larger quantities can reduce this cost).

If you are currently in soap business, consider, when you sell a bar of soap, how long will the bar last before the customer returns for another, whereas bath bomb is a one time product with a high profit margin that can increase repeat business in your store.

What are the advantages of your machine?

With our independent R & D team, we can design and manufacture each project according to customers' individual needs, and then you can use our machine to produce your ideal bath bombs.

We designed our Pneumatic Bath Bomb Press as a desktop type, it’s compact, lightweight and space-saving, you can use it in your garage or kitchen.

It is simple and fast to operate and it comes fully pre-assembled, all you need to do is connect it to an air compressor then you are ready to start molding your ingredients into various shapes of bath bombs, this all takes just 5 minutes.

Can I visit your factory in China?

Yes. you are warmly welcome to visit our factory and experience our machine for yourself.

We are sure you will be impressed.

What information do I need for a quote?

Some of the basic information we need includes the shape and size of the bath bombs you need to produce and how many bath bombs you need to press at a time.

What are your payment terms?

We accept 50% T/T deposit before production and 50% T/T balance before shipment.

Our payment terms include EXW, FOB, CFR, and CIF.

How do I test the machine before shipping?

We rigorously test each machine prior to shipment to ensure performance and quality.

We also provide test videos to our clients for review and approval.

How long does it usually take to receive machine?

The general lead time is 5-7 business days from order date.

We ship worldwide but we are not responsible for any taxes, duties or customs that you may have to pay at the time of delivery.

Do you provide overseas after-sales service?

We warrant that our Pneumatic Bath Bomb Press will be free from material and manufacturing defects, ensuring satisfying functionality under normal usage conditions.

For any questions during machine operation, contact us via e-mail for prompt support, we can provide remote troubleshooting and problem solving support, you don't have to send us your machine.

Our machines come with an 18 month warranty (excluding molds), but the warranty is void for unauthorized repairs, alterations, or damage caused by misuse.

Cautions for operation!

When in use, ensure machine stability by placing it horizontally, preventing lateral loads on the piston rod that could cause substantial damage to the cylinder.